FR-4 pcb manufacturing companies in PE(Peru)

- Author:Admin

- Time:2023-11-21

- Browse:

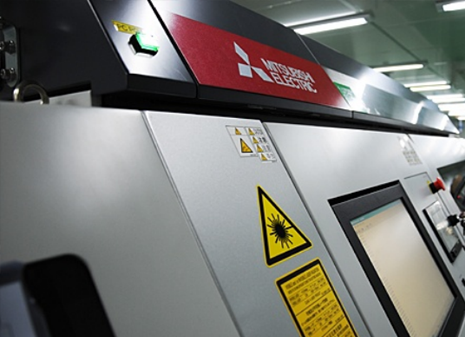

Semshine owns more than 20000 sqm of plant with over 60000 sqm per month production capability; and possesses the latest professional Fully automated equipment production line to handle the PCB, including double-sided, multilayer, and HDI PCBs, etc. It can be widely applied to a variety of fields, such as communication, medical equipment, consumer electronics, Vehicle Electronics, etc.

What is FR-4?

FR4, also written as FR-4, is both a name and a standard rating. The name is applied to the fiberglass-reinforced epoxy-laminated sheets used in printed circuit board manufacturing. However, the name also functions as a grade used to rate epoxy laminate sheets. The designation essentially indicates the base quality of a laminate sheet, meaning a variety of sheet materials and designs fall under the FR4 rating. The “FR” in the name stands for flame retardant, while the 4 differentiates the material from others of the same class.

FR-4 VIDEOS

Semshine Technology Co., Ltd, which has specialized in making PCB since 2006, offers one-stop PCB manufacturing services, ranging from raw material and electronic components procurement, and PCB fabrication, to PCB assembly, testing, and after-market service.HOW IS FR-4 USED IN PCBS?

These qualities make FR4 an ideal default substrate material for quality PCB manufacturing processes. When used appropriately, these properties can also form the foundations of high-quality and low-cost PCBs.

Within a PCB, FR4 forms the primary insulating backbone. This is the base upon which the manufacturing company builds the circuit. Once prepared, the FR4 board is laminated with one or more layers of copper foil using heat and adhesive. This copper forms the circuits in the finished product and may cover one or both sides, depending on the design of the board.

Complex PCBs may use more than one side or even layer the circuit board to produce more sophisticated circuits. From here, the circuits are drawn and etched out before being covered with a solder mask layer, preparing the board for the final silkscreen layer and the subsequent soldering process.

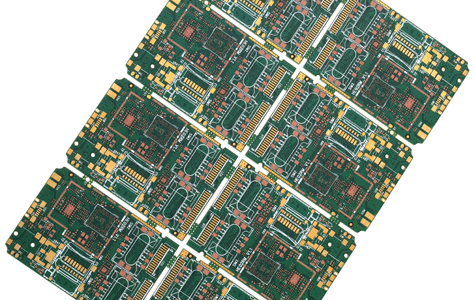

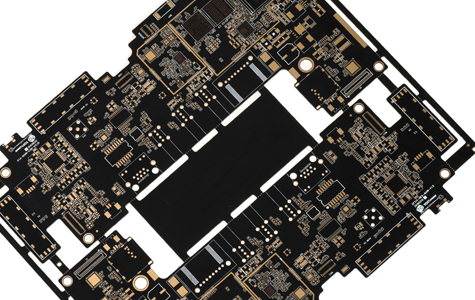

FR4 PCB Products

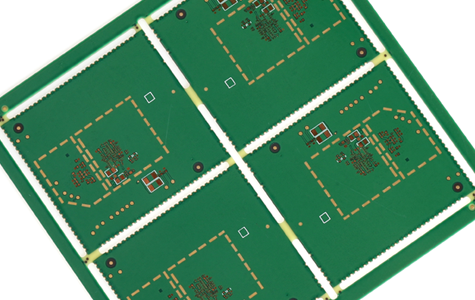

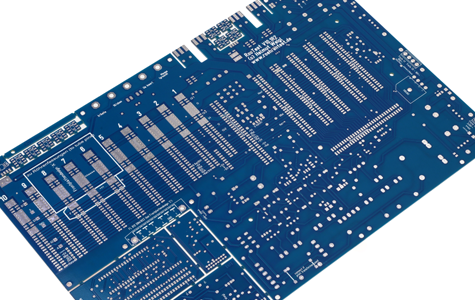

FR4 PCB Workshop

fr4 substrate parameters

Other attributes

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...