TM(Turkmenistan) pcb manufacturing,multilayer pcb manufacturing in TM(Turkmenistan)

- Author:Admin

- Time:2024-03-24

- Browse:

Shenzhen Semshine Technology Co., Ltd, which has specialized in making PCB since 2006, offers one-stop PCB manufacturing services, ranging from raw material and electronic components procurement, and PCB fabrication, to PCB assembly, testing, and after-market service.

Up to now, Semshine owns more than 20000 sqm of plant with over 60000 sqm per month production capability; and possesses the latest professional Fully automated equipment production line to handle the PCB, including double-sided, multilayer, and HDI PCBs, etc. It can be widely applied to a variety of fields, such as communication, medical equipment, consumer electronics, Vehicle Electronics, etc.

With rich experience and expertise, Semshine is your go-to choice for a China PCB manufacturer. We are looking forward to establishing a long-term cooperative relationship with you.

pcb manufacturing Types

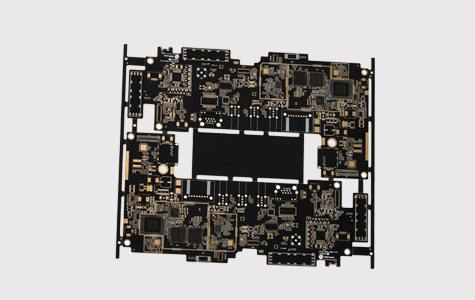

HDI PCB manufacturing

HDI PCBs are a type of multilayer PCB that utilizes advanced technologies to achieve higher circuit density and miniaturization. They incorporate microvias and high-density routing to accommodate complex and densely packed components.

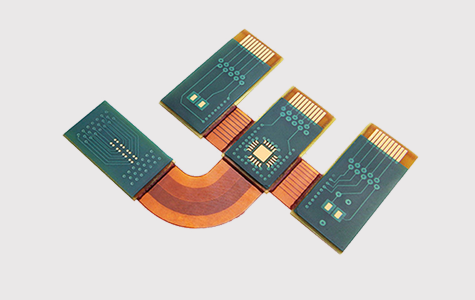

Rigid-Flex PCB manufacturing

Aluminum PCB, also known as Metal Core PCB, is a type of printed circuit board that uses an aluminum base material. It possesses unique characteristics and application advantages compared to traditional substrate materials such as FR-4. The structure of a

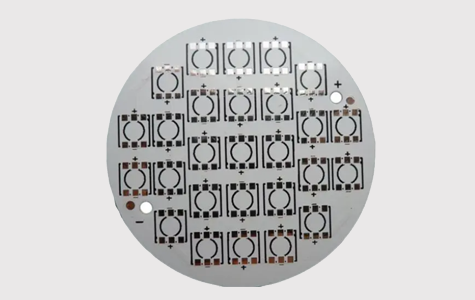

Aluminum PCB manufacturing

Aluminum PCB, also known as Metal Core PCB, is a type of printed circuit board that uses an aluminum base material. It possesses unique characteristics and application advantages compared to traditional substrate materials such as FR-4.

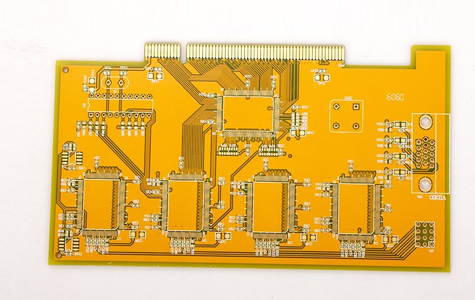

Multilayer PCB manufacturing

Multilayer PCB (Printed Circuit Board) refers to a type of PCB that consists of multiple layers of conductive traces and insulating material stacked together. Unlike single-layer or double-layer PCBs, which have only one or two layers of conductive materi

Heavy Copper PCB manufacturing

Heavy Copper PCB refers to a type of printed circuit board that features a significantly thicker copper layer compared to standard PCBs. The copper thickness in heavy copper PCBs typically ranges from 3 ounces (105 micrometers) to 20 ounces (700 micromete

Materials needed for PCB production process

The materials needed in the PCB production process mainly include copper foil, photoresist film, corrosion agent, welding film, components and so on. Among them, copper foil is the basic material of the PCB board, the photoresist film is used to make the graphics and lines of the PCB board, the corrosion agent is used to etch away the excess copper foil, the welding film is used to protect the PCB board and the welding pad, and the components are an important part of the PCB board.Equipment needed for PCB production process

The equipment needed in the PCB production process mainly includes platemaking machine, etching machine, drilling machine, coating machine, welding equipment, testing equipment, cleaning equipment and so on. Among them, platemaking machine is used to make photoresist film, etching machine is used to etch off excess copper foil, drilling machine is used to drill, coating machine is used to cover welding film, welding equipment is used to install and weld components, testing equipment is used to detect PCB board quality, cleaning equipment is used to clean the welded PCB board.pcb manufacturing Why Choose Semshine

Customer service

A special customer service team contacts customer, offers quick response and provides return and refund service.

Delivery

Before delivery, the item number, customer code, quantity and consignee etc must be fully checked by the PQA.

Test of finish product

Open/short, visual inspection and physical testing.Flying probe,ICT,and functional testing.

Control in Manufacturing

The factory has advanced automatic production line which reduces manual damage to boards.

Pre-production Arrangement

The engineer checks the customer's design information, makes the production documents twice and is confirmed by the customer.

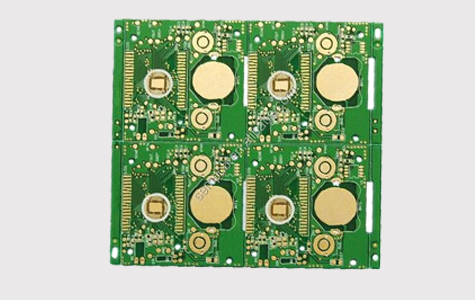

PCB manufacturing workshop

-

PCB manufacturing workshop

PCB manufacturing workshop

-

PCB manufacturing workshop

PCB manufacturing workshop

-

PCB manufacturing workshop

PCB manufacturing workshop

-

PCB manufacturing workshop

PCB manufacturing workshop

PCB Manufacturer Capabilities

|

Category |

Description |

Capability |

|

File Formats |

Gerber files- preferred |

Gerber file 274-X or ODB++ |

|

Drill file |

3.3 leading mm |

|

|

Size |

Max. finished PCB dimensions |

400mm x 1200mm – Single/ Double-sided |

|

600mm x 700mm – Multilayer |

||

|

Board Thickness |

Standard |

1.6mm ±10% |

|

Min. |

0.6mm ±10% |

|

|

Max. |

3.2mm ±10% |

|

|

Bow and twist |

0.50% |

|

|

Copper Thickness |

Outer Cu weight |

0.5oz-12oz |

|

Inner Cu weight |

0.5oz-12oz |

|

|

Laminate Materials |

FR4(KB, ILM, Shengyi, Huazheng new material ) , |

|

|

Board Cutting |

Max. number of layers |

20 |

|

Min. thickness for inner layers (Cu thickness are |

0.05mm |

|

|

Drilling |

Min. size |

0.20mm |

|

Max. size |

6.00mm |

|

|

Drill Deviation |

±0.075mm |

|

|

NPTH hole tolerance |

±0.05mm |

|

|

Angle of Countersink |

45° |

|

|

PTH |

Min. hole size |

0.20mm |

|

Aspect ratio |

8:1 |

|

|

Etching |

Trace width tolerance |

±20% |

|

Min. trace width / space (1oz finished Cu weight |

75um/75um (3mil/3mil) |

|

|

Min. trace width / space (1oz finished Cu weight |

89um/89um (3.5mil/3.5mmil) |

|

|

Min. trace width / space (2oz finished Cu weight) |

150um/150um (6mil/6mil) |

|

|

Solder Mask |

Color |

Green,White,Black,Red,Blue,Etc. |

|

Min. solder mask clearance |

3mil |

|

|

Thickness |

Line angle:8um(min),Linear plane:10um(min), |

|

|

Silkscreen |

Color |

White,Black,Etc. |

|

Min. trace width |

100um 4mil |

|

|

Min. size |

0.7mm 28mil |

|

|

Test |

AOI |

100% |

|

Flying Probe Tester |

Sample 100% |

|

|

E-test |

Mass order 100% |

|

|

Controlled Impedance |

Tolerance |

+/-10% |

|

Impedance tester |

Test impedance module |

|

|

Profile |

Tolerance |

±0.10mm |

|

V—CUT Depth |

±0.10mm |

|

|

V—CUT angle deviation |

30° |

|

|

Semi-hole |

Minimum half hole:0.40mm |

|

|

Surface Finish |

HASL,Immersion gold(ENIG),OSP |

|

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...