FR-4 pcb manufacturing companies in MT(Malta)

- Author:Admin

- Time:2023-11-21

- Browse:

Semshine owns more than 20000 sqm of plant with over 60000 sqm per month production capability; and possesses the latest professional Fully automated equipment production line to handle the PCB, including double-sided, multilayer, and HDI PCBs, etc. It can be widely applied to a variety of fields, such as communication, medical equipment, consumer electronics, Vehicle Electronics, etc.

What is FR-4?

The material widely referred to as FR4 is a composite structure. The most basic layer of the material is fiberglass woven into a thin, cloth-like sheet. The fiberglass gives FR4 its necessary structural stability. This innermost fiberglass layer is then surrounded and bound by a flame-resistant epoxy resin. This resin is what gives the material rigidity, among its other physical properties. FR4 sheets are widely popular among electrical engineers and designers as a PCB base material

FR-4 VIDEOS

Semshine Technology Co., Ltd, which has specialized in making PCB since 2006, offers one-stop PCB manufacturing services, ranging from raw material and electronic components procurement, and PCB fabrication, to PCB assembly, testing, and after-market service.Factors To Consider While Choosing FR-4 Material's Thickness

The thickness of a PCB board plays a vital role in acquiring the desired results. The thickness of a PCB is usually measured in millimeters. For example, the thickness available for FR-4 PCB sheets ranges from 0.127 mm to 3.175 mm or 0.005 inches to 0.125 inches. However, the thickness of each board varies depending on the requirements of the project.

Connections

Two PCBs require an edge connector to join them with each other or another matching socket. The connectors are available only in limited sizes. Hence only fits a particular set of PCB thicknesses. It might be a limiting factor to PCB thickness. If the existing PCB is redesigning and is part of an old system, the thickness of the PCB must be checked twice. That is why it is considered the fundamental reason to pay attention to the board's thickness after finalizing the circuit design and before ordering it to manufacture.

Available Space

Multiple devices such as Bluetooth accessories, remotes, and memory modules do not have much space. For these types of devices, a thinner PCB is the best solution. Thinner PCBs are not only considered efficient for small electronic devices. But they are also efficient for large modules to save space within them.

Flexibility Options

Flexibility is another vital factor to consider while choosing the thickness of FR-4 PCB material. The thinner the board, the more flexible it is. Due to heat, highly flexible and thinner PCBs usually face a high risk of bending and change of angles during soldering. Heat management should be a priority in these designs.

Since thinner PCBs show efficient performance against regularly stressed and flexible products. They have wide applications in medical and automotive devices.

The flexibility requirements of boards vary from design to design. However, the thickness or flexibility of a PCB should finalize by considering its applications and environmental conditions.

Controlled Impedance

Some high-frequency/high-speed boards require controlled impedance. We know that a stable dielectric constant (Dk) and low (thermal coefficient of dielectric constant) help to achieve controlled impedance. It is crucial to keep the thickness of FR-4 material balanced. Thin PCBs face high heat and increased thermal coefficient of dielectric constant (TCDK), which causes fluctuating dielectric constant (Dk). Due to this, it is critical to maintain the thickness of the PCB to achieve a low dielectric constant (Dk).

Components Compatibility

The thickness of the Fr-4 material has its effects on components. Most components, mainly Through Hole components, work better with thinner PCBs than thicker ones.

Design and Weight Requirements

Thin boards are light in weight and reduced in size, hence convenient for consumer electronics. It is easy to carry them, and they also reduce the shipment cost of the material. But thin boards are not an answer to large boards. The increased size of the board with a thin structure can cause fractures and bend in the PCB. While, extra thick boards can take a large surface and increase the overall weight of the module/device, which has its own consequences.

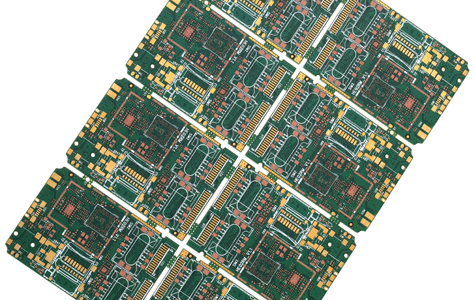

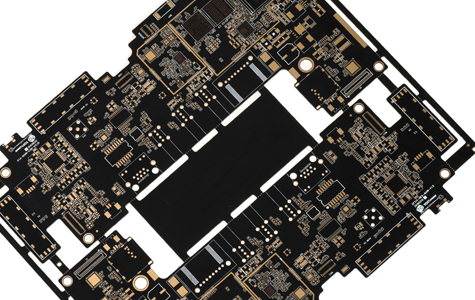

FR4 PCB Products

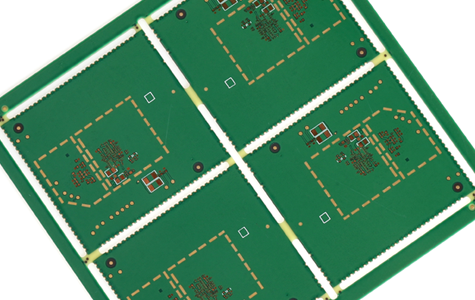

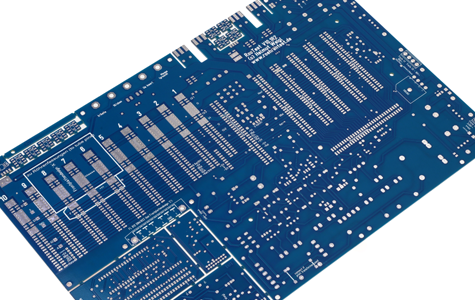

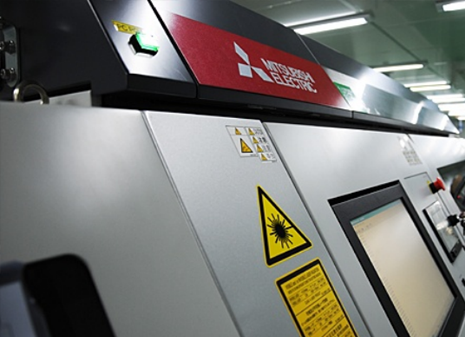

FR4 PCB Workshop

fr4 substrate parameters

Other attributes

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...