FR-4 pcb manufacturing companies in SI(Slovenia)

- Author:Admin

- Time:2023-11-28

- Browse:

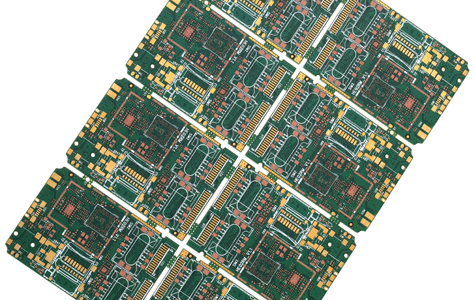

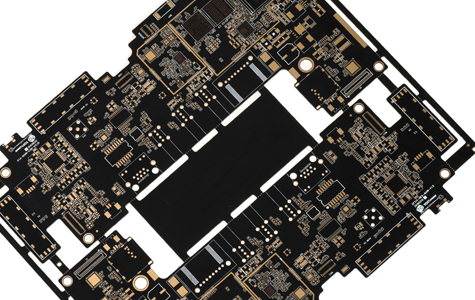

Semshine owns more than 20000 sqm of plant with over 60000 sqm per month production capability; and possesses the latest professional Fully automated equipment production line to handle the PCB, including double-sided, multilayer, and HDI PCBs, etc. It can be widely applied to a variety of fields, such as communication, medical equipment, consumer electronics, Vehicle Electronics, etc.

WHAT IS FR4 PCB?

FR4 PCB refers to a type of printed circuit board (PCB) made from a specific grade of fiberglass-reinforced epoxy laminate material known as FR4. FR4 is the most widely used PCB material due to its excellent electrical and mechanical properties.

The term "FR4" is derived from the NEMA grade designation for the material, where "FR" stands for "fire retardant" and "4" refers to the specific resin system used. The resin in FR4 is flame retardant, making it self-extinguishing and offering a certain level of fire resistance.

FR-4 VIDEOS

Semshine Technology Co., Ltd, which has specialized in making PCB since 2006, offers one-stop PCB manufacturing services, ranging from raw material and electronic components procurement, and PCB fabrication, to PCB assembly, testing, and after-market service.WHEN TO USE FR4

WHEN TO USE FR4 Many electronics applications choose to use the epoxy-based FR4 board. Their strength, reliability and relatively low cost make FR4 epoxy substrates a logical default choice for electronics engineers. However, FR4 isn’t ideal for all situations, especially high-frequency designs. For these designs, high-frequency laminates tend to be a more common choice.Cost: FR4 Will Be Cheaper

FR4 material is a very common PCB base, primarily for its relatively low cost. High-frequency laminates, on the other hand, are considerably higher in price, which is a significant drawback for cost-concerned designers and manufacturers. This is the primary limiting factor for companies when choosing between FR4 and high-frequency laminates.

Signal Loss: Lower Df Leads to Lower Signal Loss

Signal loss is, in many cases, a critical part of a PCB design, especially in high-frequency situations where signal loss is more of a problem. For these designs, FR4 is not an ideal choice — FR4 has a higher Df, or dissipation factor, than high-frequency laminates. This means FR4 circuits will suffer more signal loss than an identical circuit on a high-frequency laminate.

The Df of FR4 is around 0.020, while the Df of most high-frequency laminates is around 0.004, a fourth of FR4’s Df. The lower the Df, the less signal loss overall. The other issue is the Df of FR4 increases as a signal’s frequency increases, meaning as the frequency of the signal increases, more signal loss occurs. Since high-frequency laminates have more stable Df characteristics, they experience less loss at higher frequencies.

Impedance Stability: Dk Stability Matters

Stable impedance is another important factor for many designs, as it often means more predictable performance, especially for larger circuits or high-frequency designs. Again in this area, FR4 and high-frequency laminates offer different results. Maintaining stable impedance requires a material to maintain a stable Dk, or dielectric constant, across the entire material as the temperature of the material changes.

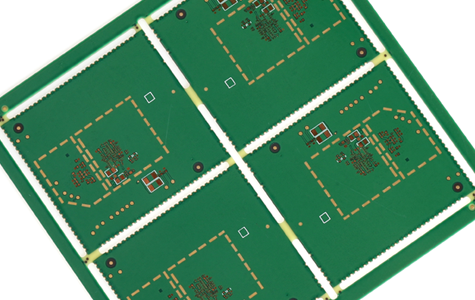

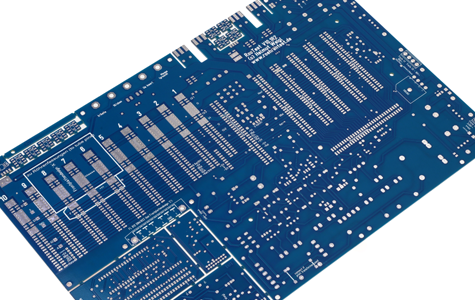

FR4 PCB Products

FR4 PCB Workshop

fr4 substrate parameters

Other attributes

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...