FR-4 pcb manufacturing companies in SL(SierraLeone)

- Author:Admin

- Time:2023-11-27

- Browse:

Semshine owns more than 20000 sqm of plant with over 60000 sqm per month production capability; and possesses the latest professional Fully automated equipment production line to handle the PCB, including double-sided, multilayer, and HDI PCBs, etc. It can be widely applied to a variety of fields, such as communication, medical equipment, consumer electronics, Vehicle Electronics, etc.

What is FR-4?

The material widely referred to as FR4 is a composite structure. The most basic layer of the material is fiberglass woven into a thin, cloth-like sheet. The fiberglass gives FR4 its necessary structural stability. This innermost fiberglass layer is then surrounded and bound by a flame-resistant epoxy resin. This resin is what gives the material rigidity, among its other physical properties. FR4 sheets are widely popular among electrical engineers and designers as a PCB base material

FR-4 VIDEOS

Semshine Technology Co., Ltd, which has specialized in making PCB since 2006, offers one-stop PCB manufacturing services, ranging from raw material and electronic components procurement, and PCB fabrication, to PCB assembly, testing, and after-market service.What are the Advantages of FR-4 Materials PCB?

Low-Cost Material

FR-4 printed circuit board material is widely available and low in cost. Still, they provide exceptional quality functioning. However, the price for a high glass transition temperature and high comparative tracking index material is a bit high.

High Dielectric Strength

FR-4 material provides high dielectric strength somewhere between 4.25-4.55 depending on different factors such as glass weave style, thickness, resin content, and copper foil roughness. The dielectric strength defines the maximum electric field that a dielectric material or insulator can resist either without breakdown or becoming electrically conductive. So, choosing a material with higher dielectric strength guarantees the exceptional quality of the insulator.

Load Bearing

As we know that FR-4 is a combination of fiberglass and epoxy resin, and it provides high load-bearing capacity and mechanical strength to the overall PCB. But mainly, the strength and load bearing depend on the thickness of the material. The thickness of a standard FR-4 material varies between 0.2 to 3.2m

Moisture Resistant

FR-4 provides moisture resistance. Humidity cannot affect FR-4 printed circuit boards such as contracting and expanding them. However, moisture absorptions affect the electrical and thermal of the material as well as the power of the material to resist conductive anode filament (CAF) formation when the circuit is powered on. Therefore, providing high moisture resistance gives an edge to FR-4 to use as the base PC material and makes it compatible to use under highly humid areas and other marine PCB applications.

Higher Glass Transition Temperature

FR-4 is highly temperature resistant providing a Tg value of 150Tg or 170Tg. The Tg denotes the glass transition temperature of the PCB. Glass transition temperature defines at which point or temperature the PCB will start getting softened and losing its shape. That is why the Tg value of PCB matters a lot. Because a higher number of Tg values ensures better performance of PCB. The Tg value of PCB not only affects temperature resistance but also affects moisture and chemical resistance.

Higher Decomposition Value

The decomposition temperature (Td) defines the temperature where a PCB's almost 5% of the laminate's mass is lost due to decomposition. FR-4 PCB material provides a higher decomposition temperature of >345 Celsius. A high decomposition temperature offers better protection and long life for the printed circuit board.

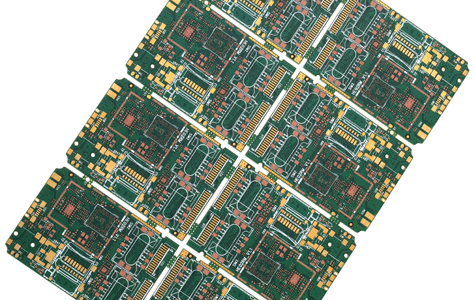

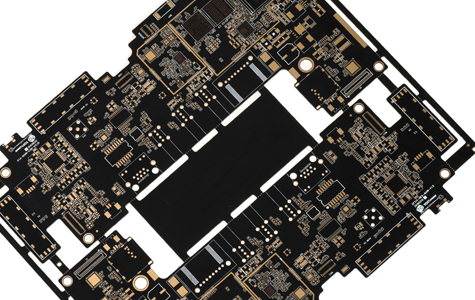

FR4 PCB Products

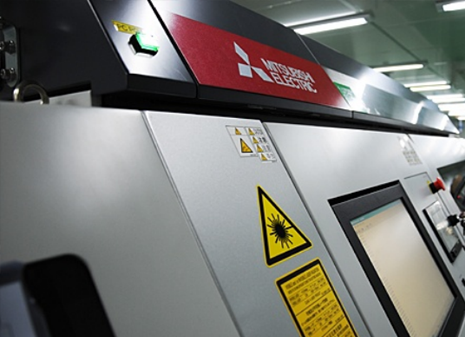

FR4 PCB Workshop

fr4 substrate parameters

Other attributes

Disclaimer: All works (images, text, audio, and video) on this website are compiled from internet sources for the purpose of learning and communication among users. If your rights have been infringed, please contact the administrator to request removal.

https://www.sempcb.com/

Related Blog

- ZW(Zimbabwe) pcb manufacturing,multilayer pcb...

- VE(Venezuela) pcb manufacturing,multilayer pc...

- UM(USMinorOutlyingIslands) pcb manufacturing,...

- AE(UnitedArabEmirates) pcb manufacturing,mult...

- TM(Turkmenistan) pcb manufacturing,multilayer...

- TJ(Tajikistan) pcb manufacturing,multilayer p...

- SH(St.Helena) pcb manufacturing,multilayer pc...

- ZA(SouthAfrica) pcb manufacturing,multilayer ...

- ZR(Zaire) pcb manufacturing,multilayer pcb ma...

- ZM(Zambia) pcb manufacturing,multilayer pcb m...

- EH(WesternSahara) pcb manufacturing,multilaye...

- VU(Vanuatu) pcb manufacturing,multilayer pcb ...